AMERICAN CLICKER PRESS COMPANY

SUPERIOR PRODUCTS START WITH SUPERIOR PRESSES

Visit our new website Hammerheadindustrial.com for updated information.

Here at the American Clicker Press Company...

From Design

We work with you to solve the headaches and remove the friction.

To Development

Professional design, proven components, and rugged materials.

From Integration

Complete machine testing to ensure all the requirements are met.

To Installation

Training, trial runs, support, and service.

we've got your back!

FAQs

At American Clicker Press, we prioritize understanding your specific product and process needs. We are a processes company, not just a product company. We analyze material details, throughput speed, production rate, safety requirements, compliance, certification needs, and other critical factors to design the optimal machine for you. Sometimes this results in a standard model, sometimes it means creating a customized solution.

Our focus is on delivering profound value to your business with affordable, high-quality systems. We don’t just sell machines; we integrate into your team, offering tailored solutions for your unique challenges. With extensive experience in cutting machines, vision systems, robotics, packaging, and slitting, we provide comprehensive support from raw material to finished product.

Our commitment is to make reliable die-cutting machinery and automation accessible and affordable for the middle market, ensuring you have the tools needed for success.

First off, we’re engineers, not marketing experts. Since our founding in 2017, we’ve been gradually establishing our presence. Our priority has always been to design the processes and machines first, and then discuss them. This meticulous approach is a testament to our commitment to quality and reliability, even if it means our marketing efforts have taken a back seat. We believe that a well-engineered product speaks for itself, and our focus has always been on delivering exceptional solutions before promoting them.

In this industry there are many established players. Whether you’re a purchasing manager, team lead, or an owner; committing capital to machinery is a serious consideration and there’s a lot to be said about brand recognition. If you’ve had a white/blue or green/orange machine on your floor for decades it’s not an easy task to win your business. This is a perfectly reasonable position.

Our approach is straightforward: we listen to your needs, deliver the best engineering design and pricing, and leave the decision in your hands. We believe in the value of transparent communication and tailor our solutions to meet your specific requirements. Whether you choose to partner with us or not, we are grateful for the opportunity to present our capabilities and earn your consideration. Your trust in us, even just by considering our proposal, is something we deeply appreciate.

Loosely, “soft” materials. If it can die-cut we are pretty comfortable working with it.

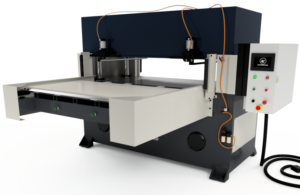

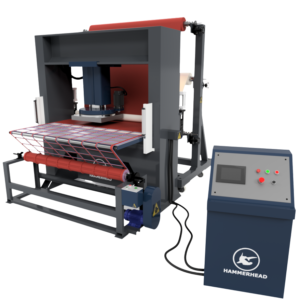

Initially, we specialized in die-cutting clicker presses. Over time, we naturally expanded our offerings to include kiss-cutting, CNC knife cutting, high tonnage and long-duration presses for applications such as jigsaw puzzles, car panels, composites, foams, and vulcanizing. This growth led us to venture into nesting, vision systems, and further automation solutions. We began integrating upstream processes like material slitters, unwinders, laminators, and welders, as well as downstream processes such as pick-and-place gantries, robotics, waste sorting, part stacking/offloading, and enhanced networking and operator interfaces.

Currently, our focus is on enhancing our machine offerings to meet better compliance and certification standards. This makes it easier for our customers to buy, install, and achieve a return on investment with our hardware. Un-designing the procurement process is a big opportunity for us to create value for our customers and we’ve pushed aggressively to streamline it.

It’s true—some of our competitors can offer machinery at a lower price than us, and that’s perfectly fine! If you’re a small leatherworker or a garage business just starting out, sometimes a lower upfront cost is what you need. We completely understand that.

However, at American Clicker Press, we strike a balance between cost and long-term value. Our machines come with a higher baseline cost due to the improvements we’ve made to ensure they are more reliable and serviceable. For instance, we have replaced all metric fittings with JIC fittings, making it easier for you to repair hydraulics locally. Our electrical designs are built with flexibility in mind, so in a pinch, you can use parts from McMaster or Automation Direct. We’ve incorporated VFDs, soft starters, oil radiators, direct-acting buttons, solid state relays, and many other design considerations to minimize downtime while staying close to our target price points.

We know that not every customer prioritizes downtime and serviceability, and that’s okay. Our business model requires the machines to have a low failure rate and high degree of productivity. There is a minimum price point for our machines below which we cannot reliably sell, support, and service them. Therefore, we do not offer machines below this threshold to ensure you receive the quality and support you deserve.

We leverage our American engineering with the manufacturing expertise of a trusted partner in China. This collaboration ensures you get a consistently reliable and affordable machine system. It’s taken years to build the relationship, trust, and processes needed to meet the high-quality standards expected by the American manufacturing base.

Our machines feature reliable and readily available brands such as Parker, Sun, Eaton, Schneider, Delta, and Mitsubishi. We frequently design machines using customer-requested hardware such as Allen-Bradley, UL certified panels, and NRTL certifications. While specific certifications must be done individually due to customization, the goal of our design practices is to consistently adhere to UL and ANSI standards.

We believe in the innovative power of the U.S. manufacturing base. Our long-term goal is to bring mid-level manufacturing back to the United States. These machines and capabilities left the US from the bottom-up on the value chain and will return from the top down. We must enable companies to bring their production back in-house with our machines and work back down the value chain until we can restore these capabilities. Once the products are made here, the production of the machines that make the products can follow. Unless we can improve the productivity and reliability of these machines at price points that enable the middle manufacturers, we’ll never bring it back.

This is our company objective.

There’s a critical point where the cost of a machine intersects with the cost of downtime. Cheap machinery may have a low upfront cost but can result in significant long-term expenses due to frequent maintenance and downtime. On the other hand, many businesses cannot afford the high six-figure price tags of many American or European-made machines that boast excellent design and engineering. Many of these machines are works of art. There’s no denying that. But the middle market where the cost of downtime and the cost of a machine are painfully balanced is where our company lives.

We combine the economies of scale, vertical integration, and manufacturing expertise of China with American engineering and design principles. This approach allows us to offer capabilities such as full automation, NRTL certifications, and bespoke design requirements at a fraction of the cost of comparable domestic systems. Additionally, we provide simple, off-the-shelf machines at competitive prices, ensuring that you get the best value without compromising on quality or reliability.

Fundamentally, we’ve taken the farmers approach to our business model. To keep the pricing low enough for our customers we can’t overdesign every component to last forever. We choose some to focus on (cylinders and seals) and make the rest easy to diagnose and replace (electronics and filters).

There are many factors to make this decision. The first and likely most important for the customer is price. Sometimes, a $10k-$20k machine that gets you into production and generating revenue is the best option. Come back after it’s proven the process/business for you and upgrade. We have been in this position as a company and we get it. Going from step 1 to step 4 is not always a wise decision even if you could manage it. Beyond that, here are some general considerations:

- What is your material?

- Soft or rigid. Thick or Thin.

- How is it delivered?

- Rolls, sheets, layered, thermoformed, etc.

- What is your biggest cutting die?

- To establish the needed cutting area.

- What’s your most complex die pattern?

- Combined with a PSI test on your material on our test bench we can establish the estimated tonnage necessary to cut your product.

- Production rate

- How fast do we need to complete a cutting cycle?

- Compliance Requirements

- Safety, NRTL, FARS requirements. Any of the certifications needed for the machinery to pass internal audits or AHJ permitting.

- How soon do you need the machine?

- Simple machines usually can be ready to deliver in a few weeks. Built to order machines with simple requirements might take 60-90 days. Complex machinery with extensive requirements could take 150 days to build, test, validate, and ship to you. The type of machine you buy is sometimes constrained by your timeline.

Since we started in 2017 we’ve sold just under 500 machines. Half of those are simple off-the-shelf systems and others are fully custom systems for small manufacturers and fortune 100 companies. All of them mark a significant amount of blood and sweat from our team to drag this dream of ours into reality.

We categorize our machines by “generation.” From 2017-2020, our designs were straightforward, with cautious engineering development. From 2020-2023, we focused heavily on quality control and design improvements, leading to significant redesigns.

Since 2023, we’ve been building our “Gen-3” series of machines, leveraging the experience and expertise of our team and partners. These machines are far more capable and reliable, with an emphasis on using U.S. components, hydraulics, and design standards to enhance reliability and productivity.

Our success isn’t measured by the quantity of machines we’ve sold but by the quality of our offerings. We strive to be more than just a reseller or distributor. We want to be a manufacturer, designer, and integrator, delivering top-tier solutions that meet the highest standards of excellence. Our goal is to provide profound value to our customers, ensuring their success and enabling them to bring production back in-house, restoring capabilities to the U.S. manufacturing base.

Let us know how we can help.

WHAT DO OUR CUSTOMERS SAY?

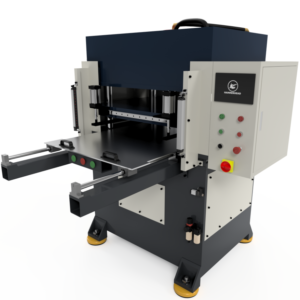

Standardized Parts

Simple swapping, simple service. All of our machines use the same parts. If anything needs to be replaced, we keep it in stock.

Easy Touch-Screen Controls

Experience simplicity with our cutting presses. Our intuitive touch-screen controls make it easy for anyone to learn how to use our machines, making your die cutting process efficient and user-friendly.

Quality Electronics

American Clicker Press provides industrial-grade PLC's, HMI's, encoders, and other electronic components, ensuring long-lasting performance and reliability in all of our cutting presses.

Quality Hydraulic Cylinders

Every hydraulic cylinder in our presses is meticulously inspected and tested. We ensure optimal installation and functionality, offering you consistent performance in your die cutting tasks.

Automatic Options

Looking to automate your cutting application? We've got you covered with advanced PLC driven automation technology, making your cutting process smoother and more efficient.

Guaranteed Shipping

Trust in our shipping process with guaranteed delivery. We ensure that our presses arrive upright and undamaged, making your investment safe and secure.

Best Warranties in the Business

Benefit from our commitment to your success with our free 1-year warranty. We also offer the option to upgrade to our premium, extended warranties, providing you peace of mind in your cutting press investment.

Get Help from our Engineers

Speak directly with one of our knowledgeable engineer staff members any time you have a question or concern about our product.

Premium Customer Service

At American Clicker Press, we value our customers. We provide unwavering support through 100% follow-through on our warranties. Loyal returning customers can enjoy free services or discounts, reinforcing our commitment to long-term relationships. We're not just a supplier; we're your partner in die cutting success.