Home » Traveling Head Press

TRAVELING HEAD PRESS

Choose Your Ideal Setup Today

Unlike full beam presses, which offer high productivity for standardized applications, our Traveling Head Presses provide unmatched versatility, enabling you to manage complex cutting tasks with ease. With the ability to lower tonnage by tackling a portion of the application at once, Traveling Head Presses are designed for medium-to-high production of intricate cuts.

Manual to Fully Automated Options

Take your production to the next level with our range of Traveling Head Presses. Whether upgrading from a Swing Arm Clicker Press with a Manual Traveling Head Press or opting for full automation with CNC nesting software, conveyor belt systems, magnetic platens, and variable degree rotating heads, we offer solutions to meet your specific needs.

Customizable Features for Complex Patterns

Perfectly nest complex patterns with features like heated platens and custom head sizes up to 30″ x 30″. Our stock models can handle materials up to 72″ wide, but custom orders for larger rolls are available. With tonnages ranging from 25 to 75 tons, and higher tonnages achievable through custom alterations, flexibility is at your fingertips.

Safety and Ease of Use

Equipped with safety light curtains and an automatic die clamping system, our Traveling Head Press ensures both safety and convenience. Intuitive touch-screen controls facilitate easy setup and operation, making your work efficient and user-friendly.

Four Levels of Automation

Choose from four distinct levels of automation to match your production needs: manual, sheet feed, pinch roller fed, or conveyor fed styles.

Invest in Versatility with Traveling Head Press

At the American Clicker Press Company, we offer state-of-the-art Traveling Head Presses to help you achieve precise and efficient cutting. We offer custom daylight, tonnage, cutting Contact us today to explore the best setup for your unique applications.

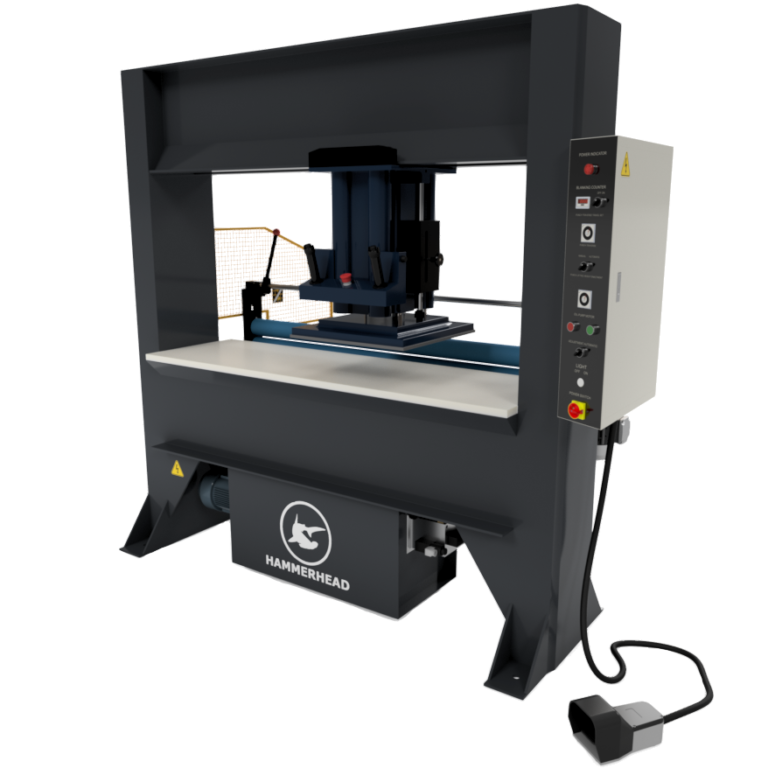

Based on the original atom clicker manual traveling head design; this die cutting press machine allows the operator to manually place material, align the cutting head, initiate the die cut, and retrieve the cut material.

From leather to industrial fabric, it fits various materials and applications. Enhance efficiency with a pinch roller upgrade controlled by a foot pedal.

Whether you need a small clicker press or a full-fledged industrial die cutting machine, this model offers an introductory solution for all your die cutting needs.

SHEET FEED

The Sheet Feed Traveling Head Press combines manual handling with intuitive touch-screen controls. Manually place a sheet (or use our scissoring sheet feeder), then adjust parameters like material advancement distance, head travel distance, and dwell time.

Ideal for cutting foam, corrugates, and standardized sheet sizes, this die cutter press suits all types of industrial die cutting.

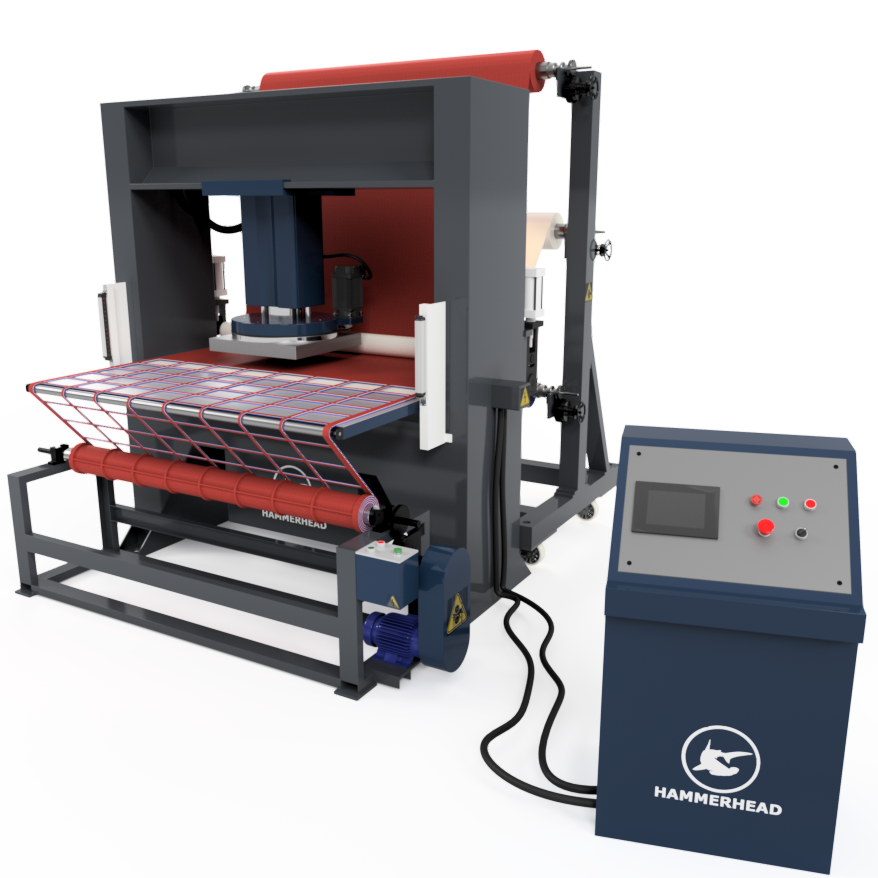

Automate rolled material cutting with the Pinch Roller Traveling Head Press. Cost-effective and efficient, this die cutting press feeds material through pinch rollers, keeping it aligned and free from bunching.

Suitable for thicker, more rigid substrates, this hydraulic die press machine offers advanced nesting using parameter-based PLC technology. For thinner materials it must be paired with a rewinder.

This hydraulic cutting press benefits from the same design advantages as a pinch-roll beam press but with the versatility of a swing arm clicker press.

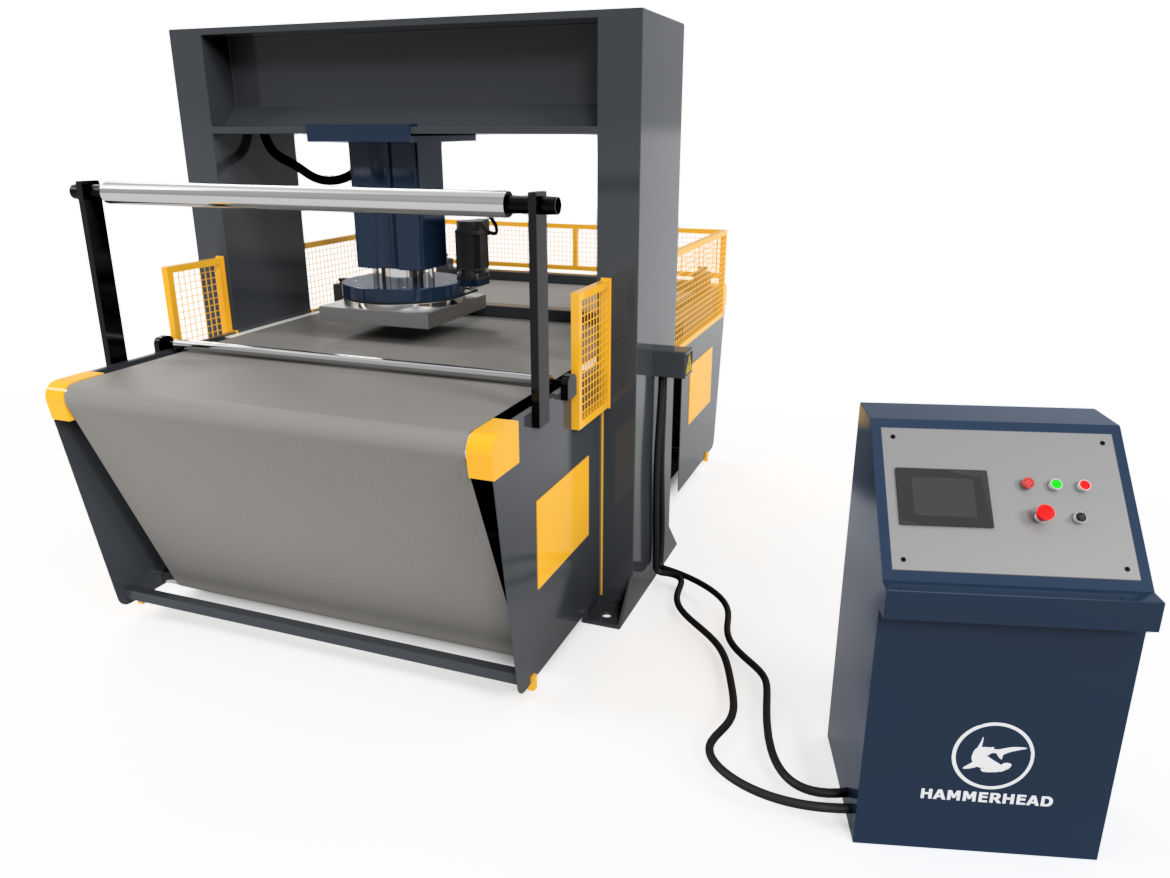

Step into full automation with the Conveyor Traveling Head Press. From handling various substrates to advanced nesting with parameter-based PLC or full CNC software, this hydraulic clicker press is a powerhouse.

Equipped with servo driven stops to protect the belt and joiner-free belt replacement design; this machine allows for fast production, setup, and maintenance.

It reads .dxf files and other project files, pulling materials effortlessly through the throat. As a commercial die cut machine, it’s ideal for all types of die cutting, whether you’ve previously been using a beam press or swing arm clicker press.

Questions? Call (801) 613-7997 [Sales]

Get In touch

(801) 613-7997

Available from 9:00 – 18:00 Mountain Time

Address: 587 W 1000 N, Suite 201

Spanish Fork, Utah 84660

Email: [email protected]