Home » Swing Arm Clicker Press

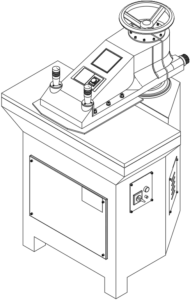

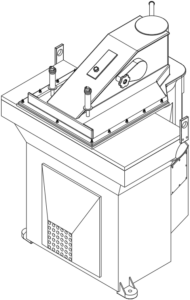

The Hammerhead Swing Arm Clicker Press

A Modern Cutting Solution - Inspired by the Best - Designed for You

10 TON

SWING ARM CLICKER PRESS-

HEAD SIZE: 13.75"W x 17.5"D

-

TABLE SIZE: 31.5"W x 15.75"D

-

STROKE ADJUSTMENT: 1.5" - 4.75"

-

MAX DIE DIMENSION: 13.75" x 15.75"

15 TON

SWING ARM CLICKER PRESS-

HEAD SIZE: 15.75"W x 18.5"D

-

TABLE SIZE: 35.25"W x 16.25"D

-

STROKE ADJUSTMENT: 1.5" - 5"

-

MAX DIE DIMENSION: 16.25" x 15.75"

20 TON

SWING ARM CLICKER PRESS-

HEAD SIZE: 14.5"W x 19"D

-

TABLE SIZE: 35.5"W x 17"D

-

STROKE ADJUSTMENT: 1.5" - 5"

-

MAX DIE DIMENSION: 14.5" x 17"

25 TON

SWING ARM CLICKER PRESS-

HEAD SIZE: 19.5"W x 22"D

-

TABLE SIZE: 39.5"W x 19.5"D

-

STROKE ADJUSTMENT: 1.5" - 5"

-

MAX DIE DIMENSION: 19.5" x 19.5"

30 TON

SWING ARM CLICKER PRESS-

HEAD SIZE: 24"W x 24"D

-

TABLE SIZE: 39.5"W x 19.5"D

-

STROKE ADJUSTMENT: 1.5" - 5"

-

MAX DIE DIMENSION: 24" x 19.5"

Reliability

HAMMERHEAD swing-arm clicker presses are engineered for exceptional durability with redesigned seals, upgraded controls, and customizable power configurations. These presses can be configured for single and three-phase power options, including 110v, 220v, and 480v, and can operate on a 15A breaker, making them ideal for both residential and light industrial facilities.

Each machine is equipped with an automatic shutoff feature that activates if a power leg is lost or if the voltage drops below a certain threshold, ensuring the motor and components are protected.

Advanced Engineering

HAMMERHEAD machienery has been tested, upgraded, and redesigned continuously to allow for a reliable and user-friendly production. These changes include:

- All metric fittings have been replaced with JIC fittings to allow for ease of maintenance and repair.

- All panels are built following best practices from UL 508(a).

NRTL Certified Designs: We offer options that comply with Nationally Recognized Testing Laboratory standards through UL508(a) and ETL certifications. This ensures adherence to stringent safety and performance regulations. Eliminate the time and resources required for qualification and validation, and begin production immediately.

Comprehensive Support and Maintenance Programs

At American Clicker Press, we stand behind our products, offering extensive support and maintenance services tailored to your specific needs. Whether it’s installation assistance, routine maintenance, or emergency support, our dedicated team is available to ensure your swingarm performs at its peak, minimizing downtime and maximizing efficiency.

Automation and Upgrades

Automation Options

- Automatic Sliding Table: Designed for sheet material, this feature enables automatic advancement and cutting, streamlining the workflow and increasing efficiency.

- In-Out Roll Feed: Ideal for roll material, this option allows for automatic advancement, cutting, and rewinding, optimizing the processing of continuous materials.

- Automatic Head-Sidestep: This mechanism automatically swings the cutting head out of the way after a cut, significantly reducing operator fatigue and enhancing productivity.

- Encoder Set Cutting: This feature uses an encoder to precisely set and save cutting positions for different applications, allowing for easy recall and consistent results across various tasks.

Add Your Experience to our Customer Reviews

TECHNICAL INFORMATION

FAQS

- Rubber & Gaskets

- Leather

- Foam

- Textiles

- Abrasives

- Other non-ferrous substrates

This Swing Arm Clicker Press is also commonly referred to as a:

- “Swing Arm Press”

- “Clicker Press”

- “Swing Beam Press”

- “Leather Press”

Swing Arm Clicker Presses are built very specifically and aren’t modular enough to add automation capabilities in most cases. For simple automation options, speak with our engineering team. For high-production automation options, visit our Mini Beam Press page.

REQUEST A QUOTE!

The American Clicker Press Company has friendly staff waiting to take your call

(801) 613-7997

Available from 9:00 – 18:00 Mountain Time

Address: 587 W 1000 N Suite 201,

Spanish Fork, Utah 84660

Email: [email protected]